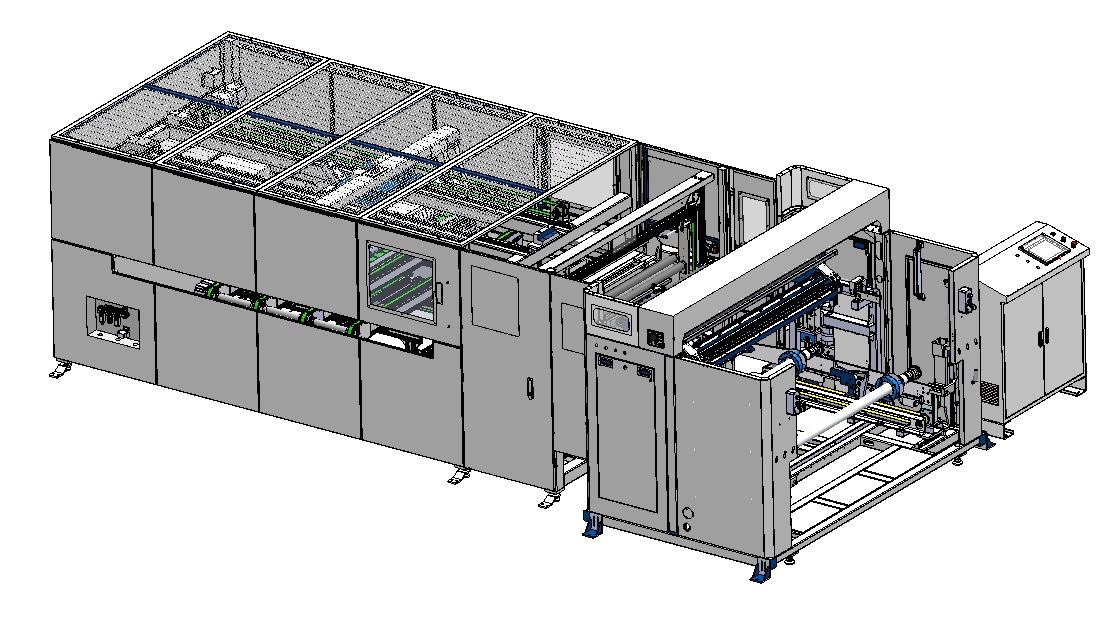

Inline EVA&B/S Cutting & Laying

Name:

Inline EVA&B/S Cutting & Laying

Introduction:

This unit is composed of EVA&B/S cutting machine, laying manipulator and control system. The manipulator is set in the discharging platform of EVA&B/S cutting machine, garbing and laying automatically. Fully cooperate with the production line, which not only improve the production efficiency but also reduce the work intensity of the worker.

Advantage:

Scope of application: applicable to EVA&B/S traumatically cutting and paving.

Material feeding unit The spindle in the material roll is pneumatic shaft, the material roll is located after the pneumatic shaft is aerated. The material roll can be pushed into the working position after lifted pneumatically. Motivated by gear motor, the material is pulled out from material roll and the wrinkles are removed through the stretch roll. Tension can be changed by adjust the torsion spring in stretch roll, as a result the thin film in different materials can be smoothed.

Cutting unit Material feeding in this unit is controlled by servo motor, and can be cut as the customer’s requirements on length and width. The material is cut when transmitted to the setting position, the cutting tool is double cylinder controlled, the cylinders work synchronously as the crank shaft connect them. With certain included angle of cutting tool, cutting will go on smoothly.

Configure:

- Rated Power: 7.0 kW

- Input Power:3P5W AC380V

- Frequency: 50/60 Hz

- Compressed Air:300.0 L/min

- Air Pressure:0.6-0.8MPa

- Equipment Size:6300*3000*1900 mm

- Net Weight:3500.0 kg

- PLC:I-CON/Inovance

- Servo Motor: I-CON/Inovance

- Switch/Sensor: Schneider/Omron/Keyence/BOE and other equivalent brands

- Motor:ZD/GPG

- Solenoid Valve:Airtac

- Vacuum Generator:Ginier/AMILA

- Compatible Roll Diameter:≤700 mm